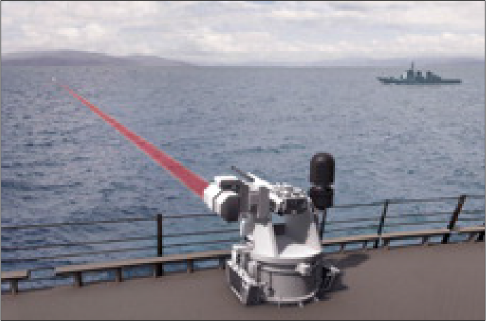

A high-energy laser is a type of light source that can produce a high-energy light. It is often used for military purposes, sometimes referred as a Tactical High Energy Laser. These lasers are strong enough to cause death in the shortest time possible. This type of laser can also be used in mobile applications.

Optic pumping

Optical pumping involves the transfer of a photon from one state to another in a laser. The pumping process is governed by the energy levels at which the photons are excited. This influences the wavelength of the laser beam as well the gain bandwidth. We will now discuss the interactions that can lead to population conversion.

High-power operation can reduce the beam's wavelength and may also cause non-linear phenomena. The fibers' coupling efficiency limits the effectiveness of pumping. Although longitudinal pumping can be very effective, it can also achieve long gain lengths. However, beam collimation can be a problem with this technique. Optical pumping at high energy lasers requires an expensive ionized gases such as xenon. This gas has wide absorption lines and is therefore very costly. It can be scaled by using more readily accessible gases, like argon.

Lamp-pumped lasers

Lamp-pumped, high-energy lasers have many benefits. They are more repeatable than end-pumped and consume less power. Their lower energy per pulse is their main drawback. They also have a lower energy per pulse, so pushing them to higher repetition rates can increase their pulse-to–pulse noise. However, recent designs have produced Nd-YVO4 lasers with 500 kHz repetition rates and low pulse-to-pulse noise.

Other advantages of lamp-pumped high-energy lasers include their compact size. They have a narrow output beam and tight focusing. Additionally, they can be used for high spatial resolution and repetition rates. Moreover, these lasers are compatible with lower-voltage utilities. They are also compact, which helps to reduce the overall footprint.

Coherent beam combinating

Coherent beam combination is used to produce high-energy laser pulses with uniform polarization. This technique has many advantages over wavelength beam control, such as higher spectral brightness, and is more suitable for high-power applications. However, this method requires high-energy lasers with narrow linewidth and high power. To make it work, the beams must be phase-matched and the lasers should operate in a single frequency mode.

Combining coherent beams is a promising way to improve the quality and output power of the laser beam. It will be vital in designing next-generation high-power lasers.

Battery capacity

The most important aspect of high energy lasers and the associated power supplies is battery capacity. The development of solid-state batteries and lithium-ion battery has also accelerated the production process. By incorporating laser technology into battery manufacturing, battery manufacturers are able to address many pressing issues related to battery cells. Lasers are used for surface structuring, electrode cutting, ablation and notching.

The battery capacity is essential to ensure the reliability of high-energy lasers systems. The battery should be able and quick to charge, and it must also be able operate for long periods. This is why the battery needs to be inexpensive and durable. The battery industry is now working to reduce the cost of battery manufacturing, and to produce high-energy cells with high power densities.

Staying strong

High-energy Lasers are capable to produce many effects. The more distant a target is, the longer a laser must stay on the target to have an effect. A laser can only have an effect on a distant target if it is within the laser's sight for a very short time.

However, the high power of a laser is problematic, as it can damage lenses, windows, and other components in the laser's path. Also, lasers can cause damage to parts used in them. Hence, if you want to use a high-energy laser, you should make sure that the material's refraction index is sufficiently low.